Return of the MACH

17 March 2022Four years after the University of Sheffield Advanced Manufacturing Research Centre (AMRC) wowed thousands of visitors to MACH by using a Caterham 7 sports car to demonstrate how Industry 4.0 technologies could assist in manufacturing assembly, the iconic racer is back.

The AMRC at MACH 2022 - April, 4 - April, 8

The Manufacturing Technologies Association (MTA), which owns and runs the biennial exhibition at the National Exhibition Centre (NEC) in Birmingham, rescheduled the 2020 event to April 2022 amid the Covid-19 pandemic. It means that the 25,000 people who visit the UK’s largest showcase of manufacturing technologies have had to wait twice as long to see the AMRC’s showpiece kit car.

But a quick look under the bonnet tells you this isn’t the same car that made petrolheads weak at the knees in 2018; it’s undergone a significant transformation to show how AMRC engineers are aiding manufacturers on their journey toward net zero.

In 2018, the Caterham 7 was on the AMRC stand under the name Project RAID (Reconfigurable Assembly Integrated Demonstrator). Now, the kit car has been transformed into a complex assembly demonstrator which displays the AMRC’s world-class capabilities in mid-technology readiness level (TRL) research across multiple sectors and capabilities.

Project ELLI (Electrification and Lightweighting in Industry 4.0) is the AMRC on tour and on four wheels.

Ejae Perez, the senior project engineer who is leading the AMRC’s involvement at MACH 2022, says Project ELLI has evolved in the two years since it was due to be unveiled to the manufacturing world at the postponed MACH 2020.

He said: “ELLI is now much more than a demonstration of electrification and lightweighting using Industry 4.0 technologies. That is still there, but ELLI has progressed to now demonstrate how manufacturers can make data-driven decisions on energy efficient products, using processes with a reduced environmental impact.”

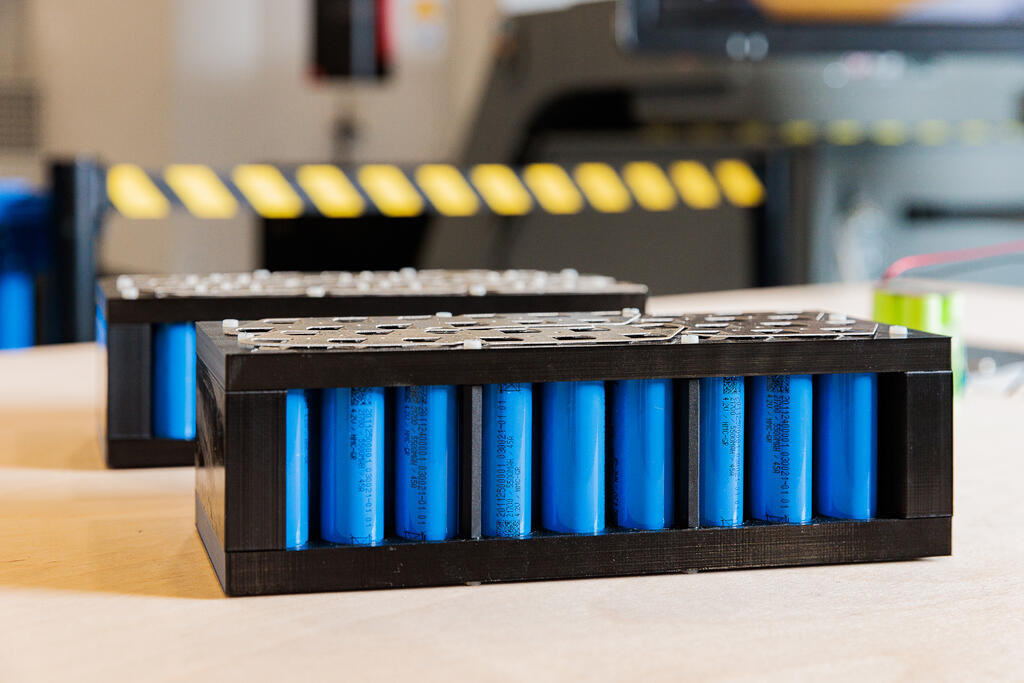

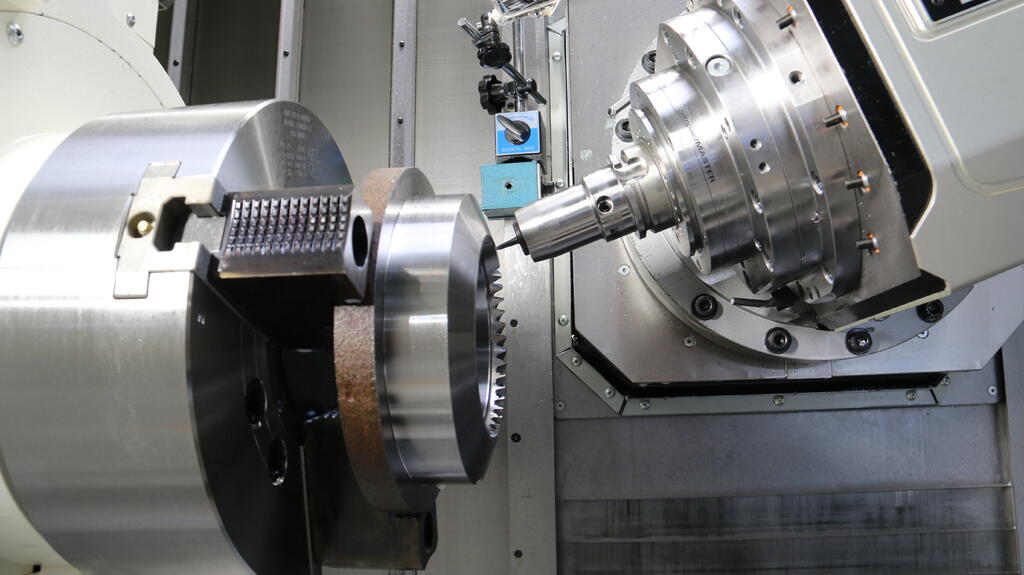

ELLI encompasses the skills of engineers across the AMRC: lightweighting with composite materials and optimal design principles, novel battery module assembly, additive manufacturing and advanced machining.

“Working collaboratively, different AMRC teams have taken components in the Caterham and applied a combination of advanced manufacturing technologies and techniques to minimise the material use, reduce energy requirements, improve in-service efficiency, or reduce the environmental impact of manufacturing processes,” said Ejae.

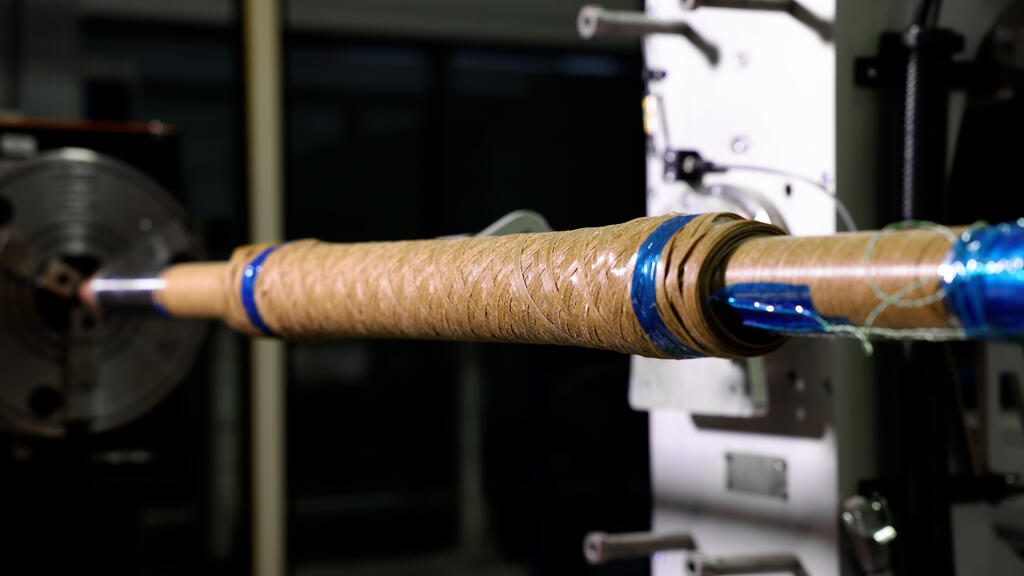

Work has centred on five elements of the Caterham: data-driven manufacturing techniques for improved sustainability in production of the Caterham’s gear differential; alternative and lightweight materials for the driveshaft; additive manufacture of topology optimised vehicle components; alternative ways to manufacture a more efficient electric motor; and laser welded battery module assembly.

Each component will be displayed on the AMRC stand with engineers on hand to explain how the advanced manufacturing technologies and techniques they have used can be applied to wider industry.

Professor Rab Scott, director of industrial digitalisation at the University of Sheffield AMRC, said: “For many people, our stand at MACH 2018 was their first real introduction to Industry 4.0. We showed them that digitalisation didn’t have to be scary or expensive, and that getting started on that journey could be relatively easy.

“Now, four years on, the message is slowly getting out that digitalisation doesn’t have to break the bank and that small steps can generate amazing returns on investment; but another message being heard loud and clear is that manufacturers need to consider sustainability in equal measure to productivity and profitability.

“Project ELLI demonstrates that shift in mindset and our engineers will be able to showcase how manufacturers, large and small, can use Industry 4.0 and other advanced manufacturing technologies to meet the demands they face in 2022.”

The AMRC’s presence at MACH 2022 extends beyond Project ELLI with machining engineers hosting a Tooling Clinic, in association with the MTA, to discuss manufacturing challenges in tooling application, cutting strategy, parameter optimisation, virtual machining, and other high value manufacturing methodologies and technologies.

At the clinic, AMRC engineers will draw on their experience and expertise, provide presentations on key discussion areas and signpost visitors to other technology exhibitors.

The AMRC is part of the High Value Manufacturing (HVM) Catapult which also has a stand at MACH 2022. The exhibition will include the Catapult Trail, consisting of stands across the NEC demonstrating how the HVM Catapult network of research centres can help companies harness key Industry 4.0 technologies.

Visit Project ELLI at stand 6-160. The Tooling Clinic is at stand 17-606 and the HVM Catapult can be found at stand 6-118.

It's the return of the MACH, yes it is.

The AMRC at MACH 2022 - April, 4 - April, 8