Digital thread: What is it?

12 February 2025In his second blog, senior theme lead for digital, Gavin Hill, explains why the AMRC landed on ‘digital thread’ as its lead terminology, and begins to untangle some of the complex language within the space.

A quick word of warning: the start of this post has a lot of undefined acronyms. I’ve done that on purpose; it shows how confusing all the different terminology in this space is at the moment. Don’t worry, they are all explained in detail later in the piece.

Right now in manufacturing, there are a lot of terms and similar sounding acronyms being bandied about casually and confusingly, and behind each of these acronyms sits a term - model-based definition (MBD), model-based enterprise (MBE), model-based systems engineering (MBSE). All of them have their place and value, but the boundaries of what they are - and are not - can be a tough topic to get agreement on. As such, there are a lot of people talking about MBD, MBE, MBSE, digital twin, digital thread and a litany of others. Sometimes interchangeably.

My belief is that although many of these terms have a clear ‘black and white’ of what they are and aren’t, others have a much larger grey area sitting in-between. We would be hard pressed to find anyone with enough conviction and influence to create 100 per cent definitive agreement on exactly where the boundaries of ‘right’ and ‘wrong’ are on this type of categorisation.

With that backdrop, we could choose to wait until the definitions settle, which may never happen, or we could be much more practical and explain things as we see them from our perspective right now, knowing that they may need refinement in the future. By having something written down, we can start to reduce the confusion and uncertainty for manufacturers who might be looking in the direction of digital thread for their business. For that reason, the AMRC has chosen to use the terminology ‘digital thread’, because we feel it is the easiest term to understand, that it more accurately describes what our customers want and do, and helps to create and shape a narrative that leads to an easier conversation with people.

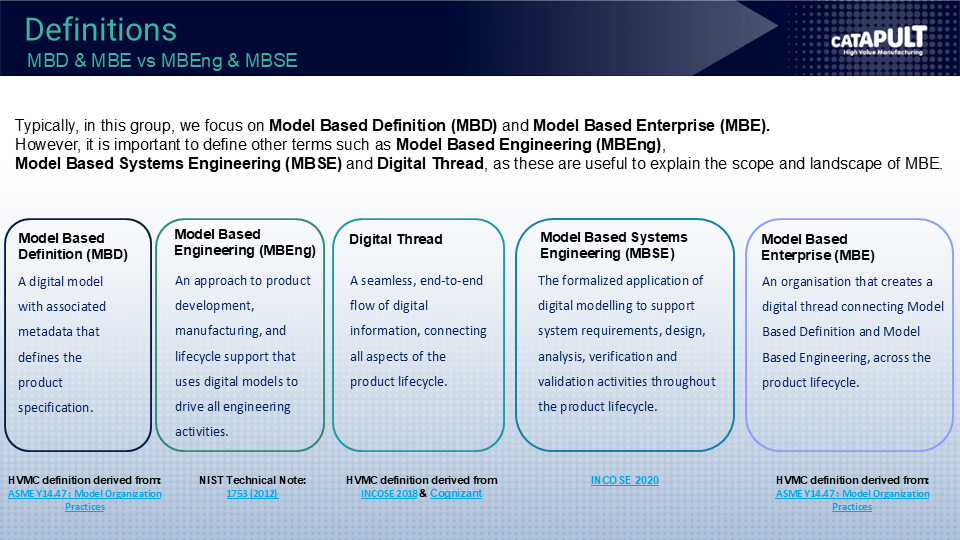

The High Value Manufacturing (HVM) Catapult MBE Working Group has been doing a great job looking at academic and official definitions of the key terms in the space, and a high-level version is shown in the picture below to give you a sense of where it has gotten to.

In this blog though, I want to depart from those official definitions; a lot of the time, they can make things harder to understand rather than easier, especially if you are new to the space. I want to focus on clarity and simplicity as much as I can, so I am anchoring this piece around layperson definitions. I will call out some of the most common terms being used, and hone in on digital thread because, as I mentioned, it is the term that the AMRC is leading conversations with.

The next few paragraphs separately address model based definition (MBD); model based systems engineering (MBSE); model based enterprise (MBE); and digital thread. I have picked out these terms specifically because, from my experience, they are both the most useful terms and the ones causing confusion for manufacturers. There are a lot of other terms that overlap into this area too, so let us know if you think we have missed anything.

Model-based definition (MBD)

This is possibly the best defined and easiest term to understand, but its scope is comparatively niche. MBD is what you get when you take a 3D CAD model and add some more information to it. Simple as that. It could be tolerances, material properties, simulation results, or any of a hundred other things. We don’t have a standard for what an ideal MBD looks like for any given part, and we probably never will; it is case, company and otherwise situationally-dependent. However, there are a lot of common areas where we can double down and learn from each other in this space.

Model-based systems engineering (MBSE)

At its core this is using connected digital tools to do systems engineering. Without systems engineering (SE) there is no MBSE. Huge advantages come to a business that implements MBSE successfully and, chances are that you would be taking advantage of elements of MBE or digital thread as well. As a result, a lot of people are using MBSE almost interchangeably as a term to describe their manufacturing digital transformation. I’m not here to be pedantic, and I can completely understand how people could get to that conclusion, but there is definitely a difference between these areas. This habit can be a significant point of confusion for many of us.

Model-based enterprise (MBE)

This is a harder one to really nail down but the easiest description is a business or ‘enterprise’ that embraces connected digital tools to make the business better than it currently is. This ‘better’ can be interpreted in all sorts of ways. The key bit for me is that MBE includes a holistic business, not just the manufacturing side. It can include everything from HR to sales, reception staff to the staff canteen. Crucially, you could implement MBE incredibly well without actually manufacturing anything; it applies as much to an accountancy firm or school as it does to a car maker - they just might not know it.

Digital thread

Digital thread can apply to a product, process or service, but for the sake of simplicity and clarity, I’ll talk about digital thread for a product. The full digital thread is all the digital information that flows through the entire lifecycle of, or is otherwise related to, a product. In general, using a part of the overall digital thread can still be thought of as a digital thread. A digital thread can be thought of as broad or narrow, thick or thin. It could incorporate every piece of data from the working practices of the company who mined the raw material and the G-code programming language for every CNC machine that touched a component in the overall product, or it could be more lightweight and just have key details on the requirements of the product and how those requirements have been met.

Similarly, if you don’t have in-depth data associated with every lifecycle stage of a product, because, for example, your supply chain is a bit less digitally savvy than you are, that does not mean you don’t have a digital thread. It just means you don’t have a full or ‘comprehensive’ digital thread. But, in my view, it is still really good progress to move towards an ambitious end goal. The inclusivity of the term is another key reason for the AMRC choosing to lead with digital thread as its chosen definition.

The table below is a subset of data from another output around digital thread from the AMRC, which will be published later in the year. The table is a bit of a ‘cheat sheet’ for the terms described.

| Name | Everyday definition | HVMC endorsed official definition |

| Model-based definition (MBD) | A 3D CAD model with additional information embedded/attached. | ‘An annotated model and its associated data that define the product in a manner that can be used effectively without a drawing graphic sheet.’ |

| Model-based enterprise | A digitally-connected business where all business functions are enhanced by access to a shared digital platform. | ‘An organization that uses digital methodologies as the foundation to enable deployment of products from concept to disposal.’ |

| Model-based systems engineering (MBSE) | Systems engineering done using digital/software tools. | ‘Model-based systems engineering (MBSE) is defined as the formalized application of digital modelling to support system requirements, design, analysis, verification and validation activities beginning in the conceptual design phase and continuing throughout development and later life-cycle phases.’ |

| Digital thread | The digital thread is all the digital information that flows through the entire lifecycle of, or is otherwise related to, a product. | ‘The digital thread is a seamless and interconnected flow of data relating to a product, following the lifecycle from design to production, sale, use and disposal or recycling.’

|

Now that you know what some of the terms being used in this space are, how do we articulate why you should care? And what difference can digital thread make to a business? I’m aiming to help answer some of these questions as we go along, but for my next blog I’ll be explaining why the AMRC is leading with, and in, digital thread.

Find out more about the digital thread here.