AMRC works with Prodrive to accelerate composites recycling challenge

11 January 2019One of the most respected and successful names in motorsport is working with lightweighting and materials researchers at the AMRC to advance its processes for manufacturing recyclable composite components that extend useful lifetimes and reduce tooling costs.

Prodrive, founded in 1984 and employing almost 500 in the UK, develops innovative engineering solutions for automotive, aerospace and marine industries. It also designs and manufactures advanced lightweight composites for a wide range of applications across automotive, motorsport, aerospace, marine, defence and other specialist sectors.

The company has been working in collaboration with research engineers at the University of Sheffield Advanced Manufacturing Research Centre (AMRC) on its P2T (Primary To Tertiary) philosophy, which is used for manufacturing recyclable composite components that can satisfy end-of-life requirements without any compromise in the performance of the original parts.

It not only simplifies recycling, but endows a composite material with the potential to fulfil three or more useful lifetimes.

Hannah Tew, Partnership Lead at the AMRC Composite Centre, said her team has been working with the company to further advance its recyclable composite process closer to full production. This has primarily focused on allowing for automation; making it possible to achieve medium to high volumes at substantially lower costs; looking at the recyclable nature of the materials used and increasing the technology’s attraction to other industries

Hannah said: “The results from our initial press trials look promising and we’re very much looking forward to supporting Prodrive in automating the process going forward.”

As P2T composites do not require heat or pressure during manufacture, there is no need for an autoclave - thus reducing costs and enabling the scaling up of production without major investment.

The process uses a reactive thermoplastic resin instead of a thermosetting type; a plastic monomer is reacted with a catalyst in the presence of the fibres to produce a cured laminate.

Prodrive Composites believe they are the first to develop this technique with recycled fibres, which emerged through a development programme with an automotive OEM customer who required a high-performance structural material with lower environmental impact than conventional composites.

“End-of-life recycling is one of the biggest debates in the composites world today,” said John McQuilliam, Chief Engineer at Prodrive Composites. “The issue affects automotive manufacturers and wider industries too, such as marine, where old fibreglass boats are often broken up and sent to landfill. The main barrier to recycling has been the type of resin used; thermosetting resins predominate but these cannot be readily recycled.

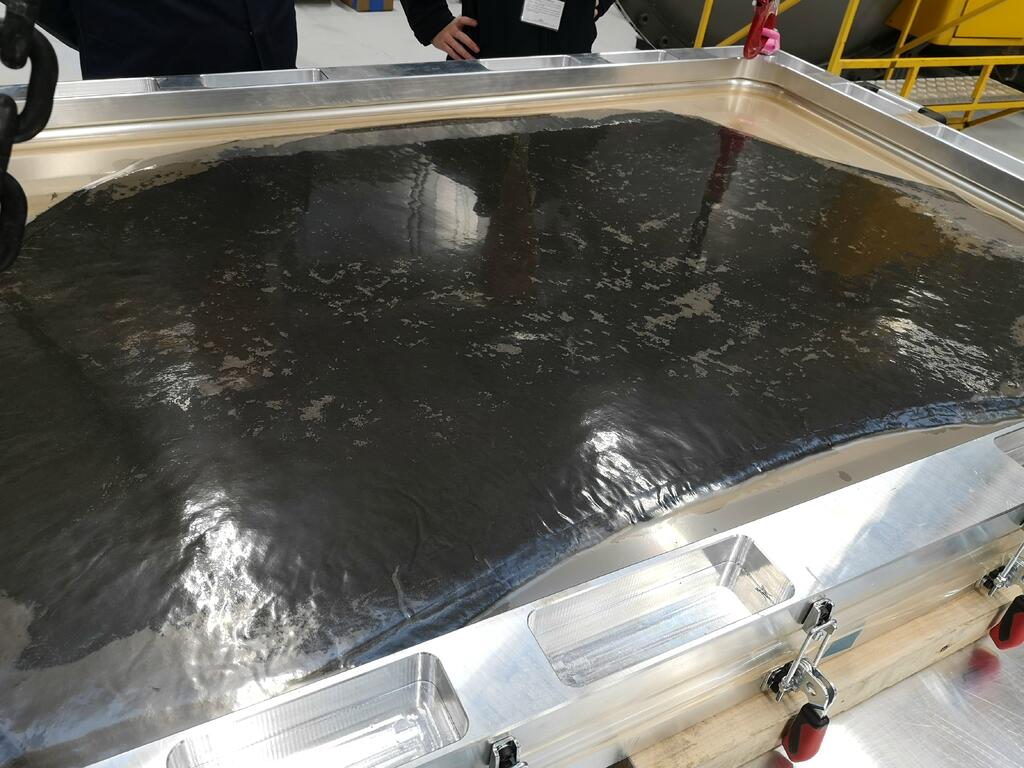

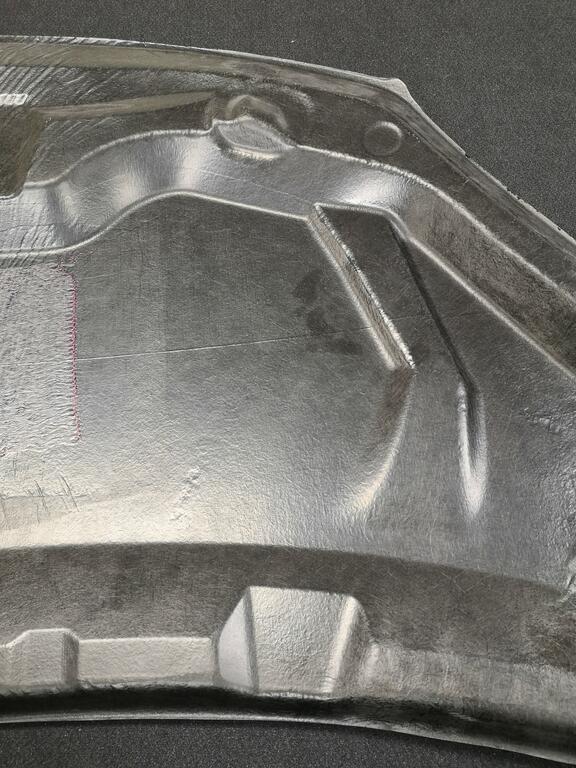

“We have been working with the AMRC and a series of large trial panels have been produced using an innovative process which can readily be automated. These trials have demonstrated that recyclable composite panels can be produced at a rate and cost to suit many industries.

“The unique feature of the P2T process is the reduced tooling cost and lead time compared to existing metallic or composite solutions.”

Traditionally, the composites industry has been based on the supply of rolls of ‘pre-preg’ (woven fibre sheets pre-impregnated with resin) which customers then lay up in moulds to produce 3D parts, curing through heating and pressurising to fix the final shape. Thermosetting resins are considered convenient materials to support this supply chain but, as tighter end-of-life regulations are introduced, better alternatives are required.

The advantages of composites produced by the P2T process is that they can be recycled multiple times. The highest mechanical properties are obtained during first use of the virgin fibres, enabling highly-loaded structural items to be manufactured.

At the part’s end-of-life, the fibres and potentially the resin can be recycled, supplying much of the raw material for a secondary part, such as a body panel. When the secondary part reaches the end of its life, being thermoplastic, it too can be chopped and remoulded into new parts with properties suitable for 3D solid components. This tertiary part can itself be recycled several times into lower grade parts.

The ongoing research between the AMRC and Prodrive Composites is set to expand considerably over the coming year and is being closely monitored by numerous companies in various industries looking to improve their environmental impact with high performance, light-weight components.