AMRC tests sustainable method for rapid materials discovery

18 January 2023A software company is using molecular modelling to speed-up the process of developing new advanced materials as part of a new project in collaboration with the University of Sheffield Advanced Manufacturing Research Centre (AMRC) and NEXAM Chemical.

Molydyn, a small Bristol-based software company, wants to simulate commercially relevant polymers using the company’s Atlas web simulation platform showcasing the benefits of computational chemistry for materials science.

Molecular modelling allows researchers to test novel materials quickly in a virtual environment, screening out candidates that don’t qualify for further study. This saves laboratories time and money by reducing their testing burden, and is a more sustainable method of research as it produces zero physical waste.

Technical lead for composites at the AMRC, Dr Gary Foster, said the AMRC is always searching for novel materials for demanding applications and that the Atlas platform created by Molydyn will help to accelerate the development of new material formulations.

Gary added: “This software package helps to reduce the amount of physical testing by replacing it with computer simulation, thus making it a more sustainable process. The AMRC will use its extensive materials characterisation capabilities to contribute to this project by validating the simulated results from the Atlas platform. It is our expectation that this will speed-up the process of developing new advanced materials for our industrial partners."

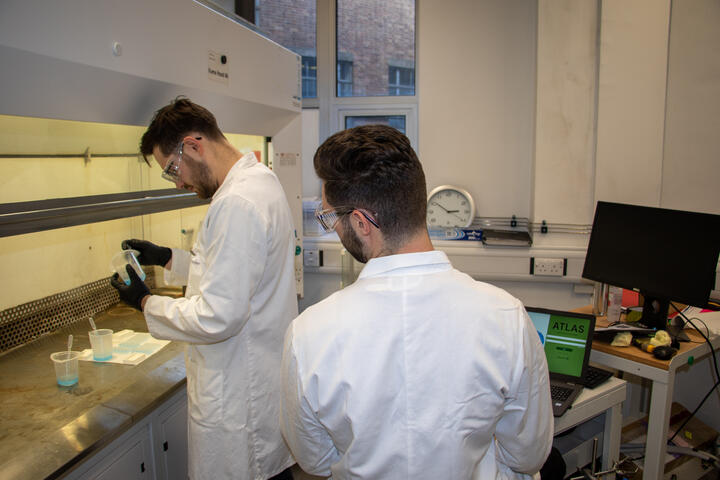

The AMRC, part of the High Value Manufacturing (HVM) Catapult network of research centres, is conducting empirical lab testing to characterise the same set of polymers Molydyn is simulating. This will act as a validation data set for current, and future, simulation research. Trialling key material properties like glass transition temperature, viscosity, and coefficient of linear thermal expansion will give Molydyn an extensive range of properties to model.

Matthew Bone, Molydyn CEO, said: “We’re really looking forward to creating good commercial case studies for materials modelling, highlighting just how quickly it can give direction for laboratory-based materials research. With Atlas, we start to make simulation tools available for all materials scientists.”

Nexam Chemical is also contributing to the project by providing one of its NEXIMID polyimide formulations for testing and simulation. The NEXIMID range is designed to increase the glass transition temperature, and improve chemical and heat resistance, for polymers operating in more demanding applications. Their involvement in this project highlights the importance that computational chemistry is expected to play in the future of innovative polymer materials.

Boyd Cushing, business development, Nexam Chemical UK, said: “To get insights into the properties and behaviour of polymeric material based on different monomer content is highly desirable for us to facilitate demanding laboratory work, i.e., synthesis, processing, and characterization. We see this new Atlas web simulation platform as a learning tool to achieve deeper understanding about the structure properties relationship between monomers and polymers.”

The project is funded by Innovate UK Edge.