Ffatri 4.0: Future production lines

Helping SME manufacturers overcome challenges of establishing smart production lines

Challenge

Disruptive technologies and trends such as the Internet of Things (IoT), virtual reality and artificial intelligence are changing the way people live and work.

This fast-paced paradigm shift in global operations and interaction has demanded the need for all industry players to begin a digital transformation journey that supports the new data-driven sustainable business ecosystem. Interestingly, companies already on this digitalisation journey would remain relevant in this new ecosystem.

Industries need guidance on how to employ Industry 4.0 concepts and technologies as they embark on this digitalisation journey, which is the main focus of this project, with findings derived from real-world scenarios.

The increasing integration of strategic innovations in Information and Communication Technology (ICT) with Operational Technologies (OT) has given rise to Industry 4.0 concepts and technologies used today, to transform existing manufacturing environments into smart manufacturing environments that support data-driven operations.

Manufacturing companies, especially small to medium-sized enterprises (SMEs), are being encouraged to understand their digitalisation needs and to develop and implement tailored transformation plans. Larger corporations may have entire teams devoted to this journey - but it’s not always the case for SMEs. Either way, there seems to be a lack of understanding on where to start, what to do, how to do it and how to evaluate the business impact.

The project addressed the challenges of establishing smart production lines using The Pudding Compartment, an SME based in Flint, as a case study.

The project framework supports industry in these key areas:

- Identification and understanding of digitalisation requirements that meets the manufacturers productivity requirements;

- Identification of improvement opportunities within existing manufacturing processes to meet the manufacturers productivity requirements;

- Identification of data required to support operational and strategic business decisions using discrete manufacturing processes, Industrial Internet of Things (IIoT) solutions and data analytics;

- Design of IIoT solutions to access, manage, analyse and visualise data gathered from a geographically remote production facility in real-time.

Background

Funded by the Welsh Government, Ffatri 4.0 is a collaboration between the University of Sheffield Advanced Manufacturing Research Centre (AMRC) Cymru, Airbus and The Pudding Compartment. It looks at how businesses can continue to increase productivity while meeting net zero carbon emissions targets through smart technologies. It is based on the premise that the sustainability and productivity goals of the manufacturing sector can be accelerated through the successful adoption and integration of digital manufacturing technologies.

The Future Production Lines project focuses on methods and technologies to establish smart production lines for The Pudding Compartment in the food and drink sector. This project investigates how novel, innovative technology can benefit industry to achieve improved production line output.

Ffatri 4.0 is a ready-to-go framework with proven success that will create a blueprint for future manufacturing companies and their associated supply chains. Through implementation and use of Industry 4.0 technologies, the framework will improve business resilience, support businesses to achieve world-class standards in productivity and support businesses on the journey to reach net zero by 2050 through efficiency improvements.

The Ffatri 4.0 R&D programme used internal expertise from AMRC Cymru and industrial partners.

Innovation

Virtual reality factory layout model

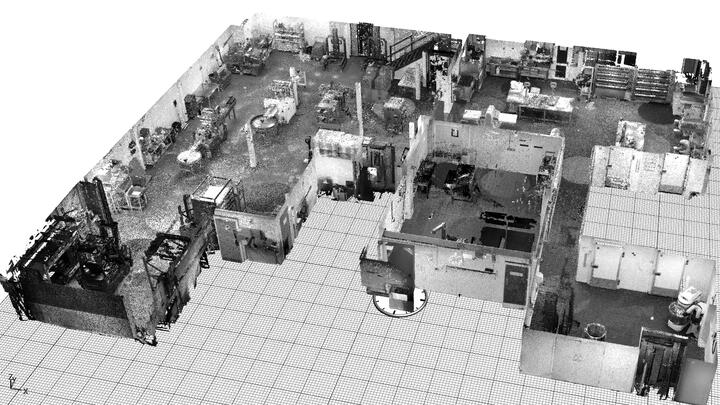

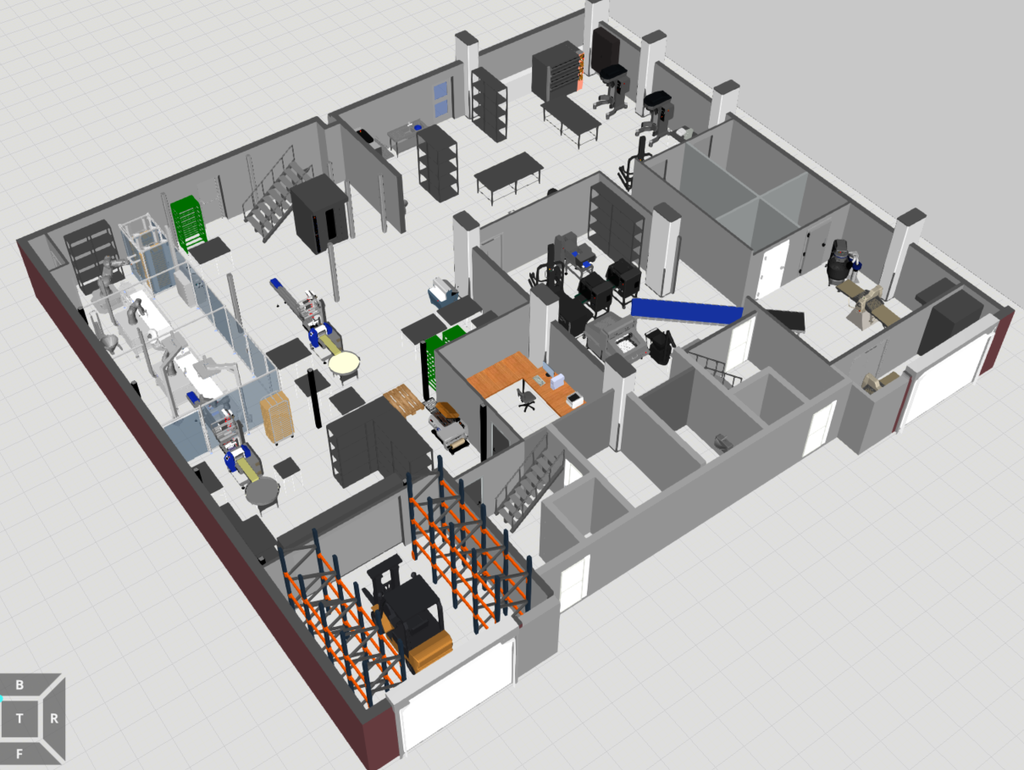

The Pudding Compartment factory was scanned and used to develop a virtual reality (VR) model of the factory. This included the factory layout, existing machineries and prospective machines. This VR model was used to analyse the factory’s layout and investigate optimal layout settings for the existing site, along with the addition of new machineries.

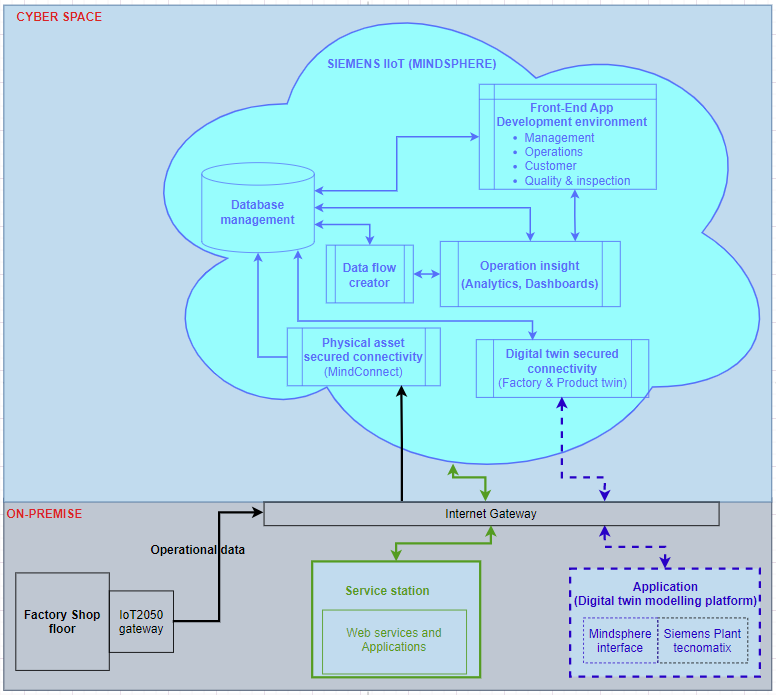

IIoT solution

An Industrial Internet of Things (IIoT) solution was developed using the Siemens Mindsphere platform, a cloud-based solution that supported the company to collect and manage its business data (business and operational). It is also able to create, analyse and visualise data in predefined perspectives. This integrated platform solution o ers digital connectivity to a physical space (on the shop floor), a database, data management applications, analytic applications and visualisation interfaces.

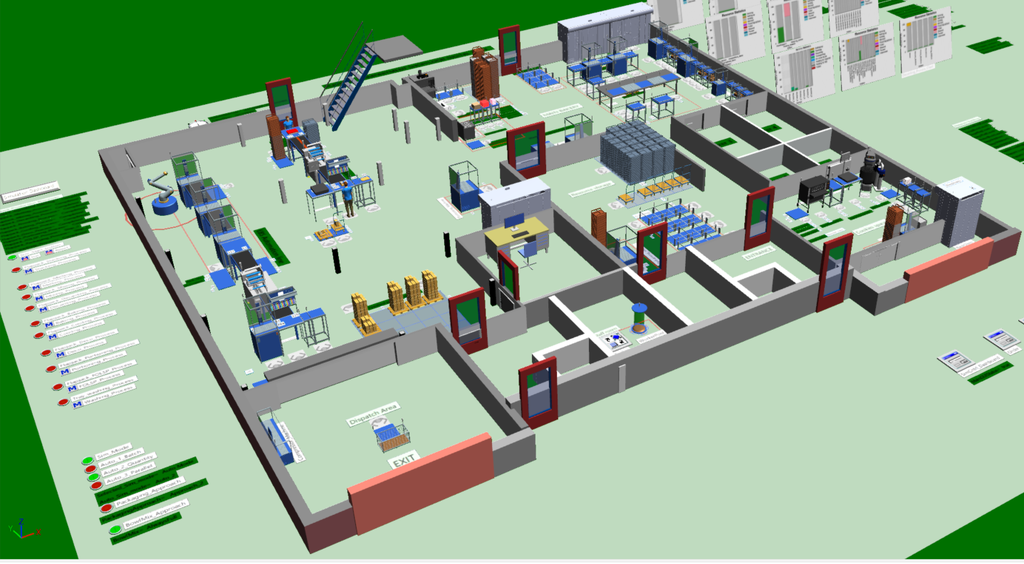

Digital twin DES model

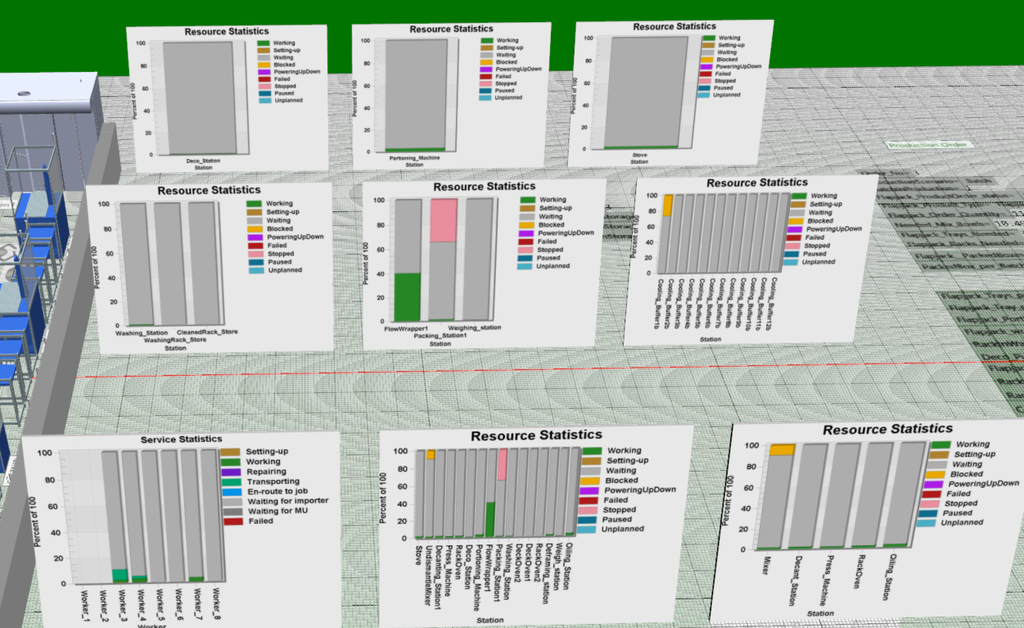

A digital twin model using discrete-event simulation (DES) was created to simulate and replay production processes, as well as generate statistical data for analytics. The model incorporates IoT data stored in the Cloud for analysis and simulation. The model can perform diagnostic analysis to identify and analyse production bottlenecks, conduct 'what-if' simulations to optimise production configurations, determine optimal machine calibrations and use predictive analysis for future production setups.

Result

The IIoT solution developed using the Siemens Mindsphere offers a comprehensive Cloud-based service that includes data management, analytics and visualisation solutions. This fully integrated IIoT environment allows seamless interconnectivity across multiple applications, avoiding bottlenecks that could disrupt digitalisation solutions and create information silos throughout a product's lifecycle.

With all product-related data stored, managed and accessible to all interested parties, this solution eliminates any potential data access issues.

The factory IoT data stored in Siemens Mindsphere was used to build more accurate, calibrated simulation models. By using this stored operational data in modelling and simulation, analytics results are more fact-based, presenting a more accurate virtual representation of the business.

With the Mindsphere Factory twin connection that links the IoT data and the digital twin model, production replay was achieved, which improves both diagnostic and descriptive capabilities of the simulation model.

Impact

It was important for the team at The Pudding Compartment to have digital tools so they could create a holistic picture of the business using real data. Engagement across the supply chain has also improved by using a digital platform.

The management team within the company now has a better understanding of their digital needs and a tailored transformation plan for business growth. And they’re now equipped with the resources to plan and manage their digitalisation journey.

Automation has increased production capacity with impacts on management and strategic planning.

The Pudding Compartment has a better dynamic template that integrates all related business and operational data with analytic capabilities, supporting daily operations and business decisions. It also has a developmental plan with a better strategic management plan, based on factual and simulation data.