Collaborative working spins out novel titanium blade hub

How does it link to the digital thread concept?

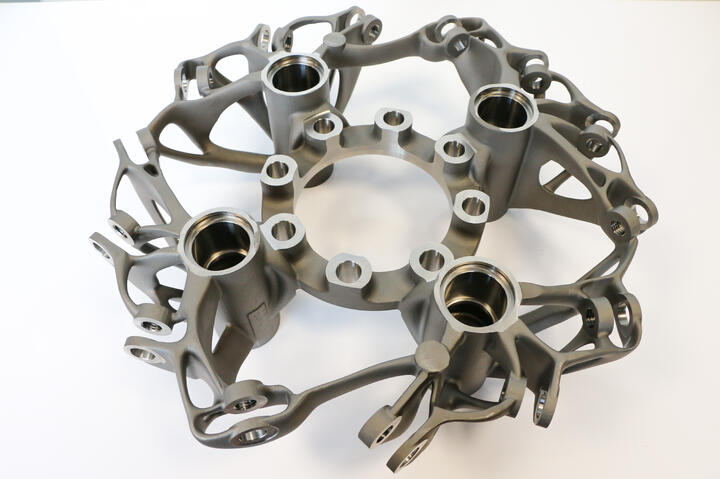

The project saw three AMRC groups work collaboratively to design, cast and machine a titanium cast blade hub for aerospace from start to finish - joining up the different steps to enable material selection, process simulation, accuracy and testing.

The use of a digital thread aims to create a ‘single source of truth’ for information exchange and connects a product’s full lifecycle with a digital master model - and could have the potential to be beneficial for this project as it could further enhance all stages of manufacture for the final goal of creating an optimised component.

Challenge

To develop a lightweight blade hub to form part of an advanced electro-mechanical pitch control mechanism for open-rotor architectures for use in the aerospace sector.

Background

The titanium cast hub was created as part of a wider project called Rotator - aimed to develop an innovative and advanced fault tolerant electro-mechanical pitch control mechanism (PCM) utilising an ultra-high torque density magnetically geared motor for open-rotor architectures.

The project, funded by Clean Sky 2 Joint Undertaking (Grant Agreement: 886986 — ROTATOR — H2020-CS2-CFP10-2019-01) aimed to achieve technology readiness level (TRL) four, which means l having the concept validated in a lab.

At the AMRC, led by our composite group, research engineers from our design, castings and machining groups collaborated to develop this highly optimised lightweight part. It is a key structural component of the motor and actuator system to deliver a step-change in motor/actuator weight-saving.

Consortium members alongside the University of Sheffield AMRC, also included:

- Magnomatics Ltd – Consortium lead

- University of Sheffield – Department of Electronic and Electrical Engineering (EEE), lead at the University.

- Romax/Hexagon

- AE Magnetics

- Safran Aircraft Engines

Innovation

To enable the successful development of the pitch control mechanism concept, the AMRC’s design group used lightweighting methodologies to arrive at a solution that met the project’s firm design specification. A thorough optimisation study, considering material selection, methods of manufacture, design envelope, and using topology optimisation, established a form that not only met the functional requirements, but also satisfied any Design for Manufacture (DfM) constraints.

The effective collaboration between the AMRC groups, design and castings, led to the successful application of manufacturing knowledge and process simulation to ensure a successful cast, first time. The as-cast geometry had considerations for machining allowances, guaranteeing features could be finished to specified tolerances which are crucial to final assembly. The final solution led to a bio-inspired geometry suited for a near-net casting in titanium (Ti6Al4V).

The casting tooling was developed and manufactured using a stereolithography additive (SLA) manufacturing moulding process which was coated with a ceramic material and, once cured, the SLA burnt away leaving an investment mould. The titanium was then centrifugally cast in AMRC Casting’s VAR titanium furnace, the largest in Europe and amongst the largest globally. The component was processed through Hot Isostatic Pressing (HIP) to ensure integrity and then chemically milled to remove the alpha case. Finally, the surface was inspected, volumetrically inspected using x-ray, and mechanically tested to certify the component.

A bespoke fixture for the hub was created by the AMRC machining group, who received the near net form from castings group. A GOM ATOS 3 scanning system was also used to accurately locate the part and adjust the machining co-ordinates to suit - giving confidence the component’s machined features are in the correct location. Adaptive machining was completed on a DMG Mori Seiki NMV8000 and the hub was milled, drilled and bored to produce the final features to an exemplary tolerance.

Result

The AMRC is unique in the fact it is one of few which can implement all stages of manufacture in house and using this joined up expertise across multiple groups as part of this project further helped to deliver a truly optimised component.

The hub passed all design requirements and was successfully cast, machined, and tested.

This project helped to build up additional experience due to the ever-increasing complexity of form. It also created further collaboration amongst three key AMRC groups and opened up a new route to manufacture for a number of engineers within the design group, opening up new realisations of the breadth of capabilities the AMRC has.

In terms of what was learnt, designing the blade hub for manufacturer was one of the largest single-piece cast components that used topology optimisation within the AMRC’s design group to date. It was centrifugally cast in titanium in the AMRC Casting’s VAR titanium furnace, the largest titanium centrifugal casting in Europe and one of the biggest globally.

It also presented a challenge for the machining team as engineers had to create a bespoke fixture to enable no movement was made to the hub during the machining process to stop any errors or miscalculations from the outset. In addition, it took out human error as the fixture enabled the adequate rotation needed for the hub during the machining process.

Impact

The blade hub project enabled the demonstration of the ‘one AMRC’ offering, where different groups collaborate to produce innovative solutions - from ideas to final component delivery. It plays a key role in the development of a fully electric innovative pitch control mechanism for open rotor aircraft engines, supporting further electrification of aircraft and contributing to reduction of the environmental impact.

The manufactured blade hub was successfully assembled into the pitch control mechanism (PCM) test rig and demonstrated the concept at TRL 4. Safran Aircraft Engines, based in France, is the topic leader of the wider Rotator project and they are in the process of developing new engines where a new PCM is required.

Ultimately, if this concept proves to be successful, it is expected to be considered for the development of the new Safran open rotor engines.