Unlocking the digital potential in composite manufacturing

17 January 2022The University of Sheffield Advanced Manufacturing Research Centre (AMRC) has worked with the National Composites Centre (NCC), Cranfield University and aerospace engineering specialists, Meggitt, to develop and demonstrate a novel sensor technology for capturing data during liquid resin processes.

The sensor system is a significant step toward the digitalisation of resin transfer moulding (RTM) by providing accurate data capture of resin infusion. This can be used to validate computer simulations of the process, enabling industry to reduce the number of initial experimental trials, facilitate a ‘right first time’ approach, crucially reducing the time and cost spent manufacturing components.

Research into dielectric sensors originated at Cranfield University before it was further developed at the NCC, a world-leading composites research centre, through its Technology Pull-Through (TPT) programme; it was then applied in industry by Meggitt. The TPT programme partners with universities to evaluate and mature their low-TRL research ready for industry adoption.

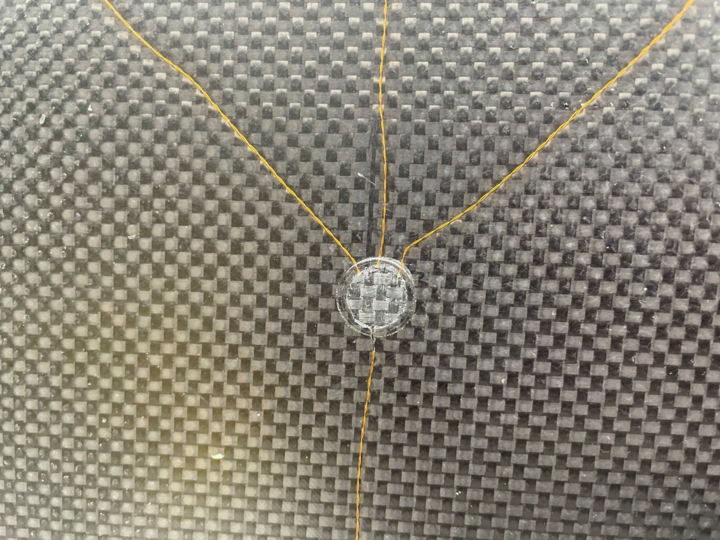

Conducting trials of the sensors at typical aerospace material processing conditions of 7 Bar and 180°C, the NCC showed the sensors could precisely detect resin as it flowed inside the preform, as well as its cure progression – both properties invisible as the process happens. Furthermore, the sensors provided no adverse effects on either the process or part quality.

Upon hearing of the successful use of the sensors in the NCC TPT programme, Meggitt approached the NCC and the AMRC to use the technology in an ATI-funded project the two High Value Manufacturing Catapult centres were conducting together to produce industrial scale aircraft components.

The NCC and AMRC teams worked alongside Meggitt to successfully integrate the sensors into a closed RTM tool, with no modifications to the tool being required. In trials, the sensors successfully captured data on the resin flow progression and degree of cure, agreeing with results from previous reports and theoretical models.

Dr Peter Karapapas, principal engineer at Meggitt, said: “We were interested in applying this sensor technology as a way of building in a smart function to the RTM process for monitoring part production. This is with the aim of minimising the time and effort required in post-production NDT and inspection on future components as we move towards digital manufacturing. The sensors were robust and effective during the demonstration on the large-scale composite housing part designed for a civil aviation jet engine air-oil heat exchanger.”

Dr Enrique Garcia, chief technology officer at the NCC, added: “A large part of the NCC’s role within the composites industry is to enable the transition of technologies from academic research to being ready for industry to use and benefit from. This project is an excellent example of this, with it being developed in our Technology Pull-Through programme, and now being utilised by Meggitt.”

To find out more about the AMRC Composite Centre’s capabilities click here.