Banking on additive manufacturing

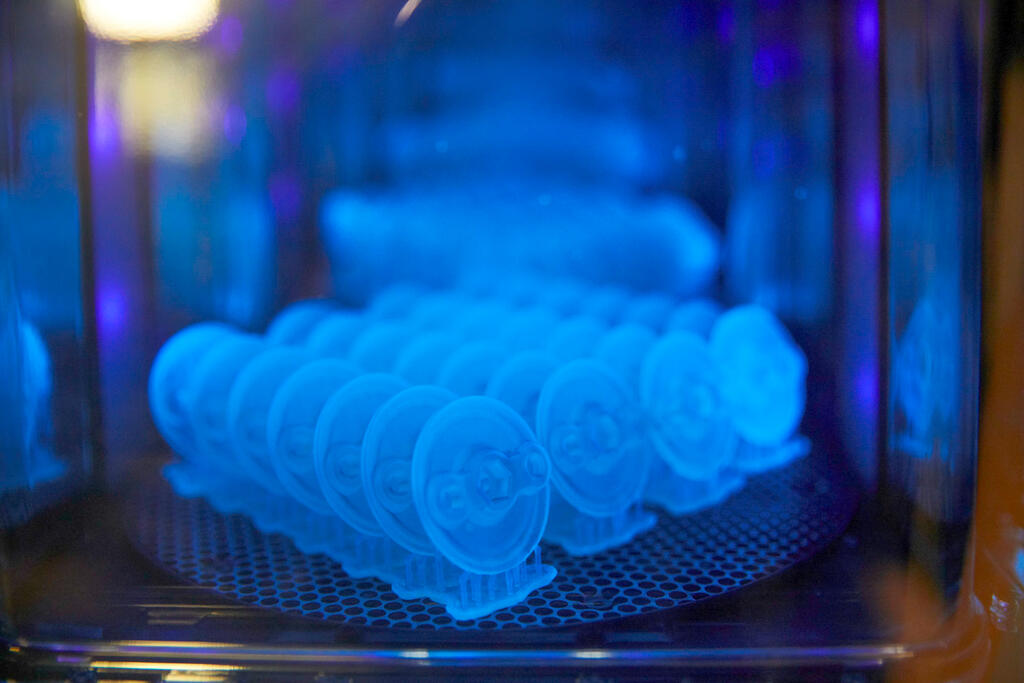

30 April 2019A bank of powerful 3D printers linked to easy-to-use software has been built by AMRC engineers to show that the batch-printing of bespoke polymer components is an affordable option, even for smaller manufacturers who are keen to accelerate their design processes, shorten lead times and drive improvements in productivity and quality.

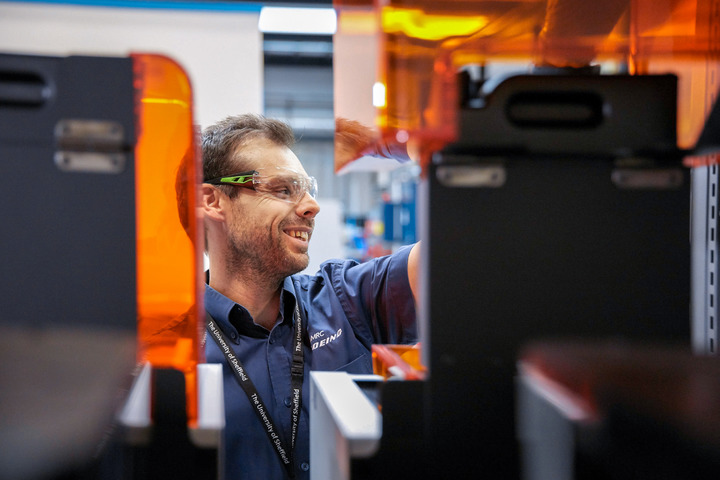

Using a fleet of 12 Formlabs Form 2 desktop 3D printers for the stereolithography (SLA) of polymer components, four Form Cure post-curing stations, four Form Wash cleaning stations and buffing capabilities, AMRC Development Engineer and AM Specialist, Mark Cocking, believes the new capability will spur the adoption of AM technology across a range of industrial sectors.

“This unique capability will be of great benefit to industry, especially to SMEs looking to explore AM as an alternative production method, and to larger companies who wish to work with us to conduct research projects into the batch-production of additively manufactured components,” Mark said.

“For firms dealing in lower-volumes of production, with special print runs or runs of multiple sets of bespoke components with small but significant changes, the bank system we have constructed provides the perfect opportunity for them to explore quickly and efficiently making design changes, producing batch volumes of multiple sets of components on the same printers,” Mark added.

The bank is installed on custom racking which connects each printer to Formlabs’ Dashboard software which gives users visibility of printer utilisation, allowing them to select a printer using the appropriate material for their print build with just a couple of clicks.

After a short 45-minute training course and completing their first print, engineers have remote access to SLA capabilities and 20 different polymer materials for a range of applications including prototyping, engineering resins and beta test materials such as ceramics for specialist applications.

The bank has already been used by AMRC research projects for global aerospace companies who want to explore the feasibility of investing in batch-printing technology to produce components of the necessary quality, within very short time-frames, and worked with them to demonstrate how designing for AM can streamline their manufacturing processes.

“The bank has been a great success with staff cross the site and we are printing well over 700 print runs every month, with over 1000 components already processed,” said Mark.

Creating open access for all was critical to the system’s success he added. “If you give engineers means to develop their own design and AM skills needed to use the print stations, they naturally develop their own use-cases for the use of AM in their research projects, from concept demonstrators to the creation of components like jigs and fixtures.”

“Once those skills and knowledge are shared and embedded, the engineers are able to draw on their wider experience and capabilities toolkit to service projects, encouraging innovation.

“Using the new capability to share knowledge and best practice with our supply chain resellers means we will be able to provide a comprehensive service to our industry partners by advising them on how they are able to access and build systems to their specification with scalable options.

“The kind of organic knowledge transfer that has come from the open-access scheme for our own engineers, could be the catalyst for our industry partners and local businesses developing valuable skills, accelerating innovations in AM for their own product lines or processes.

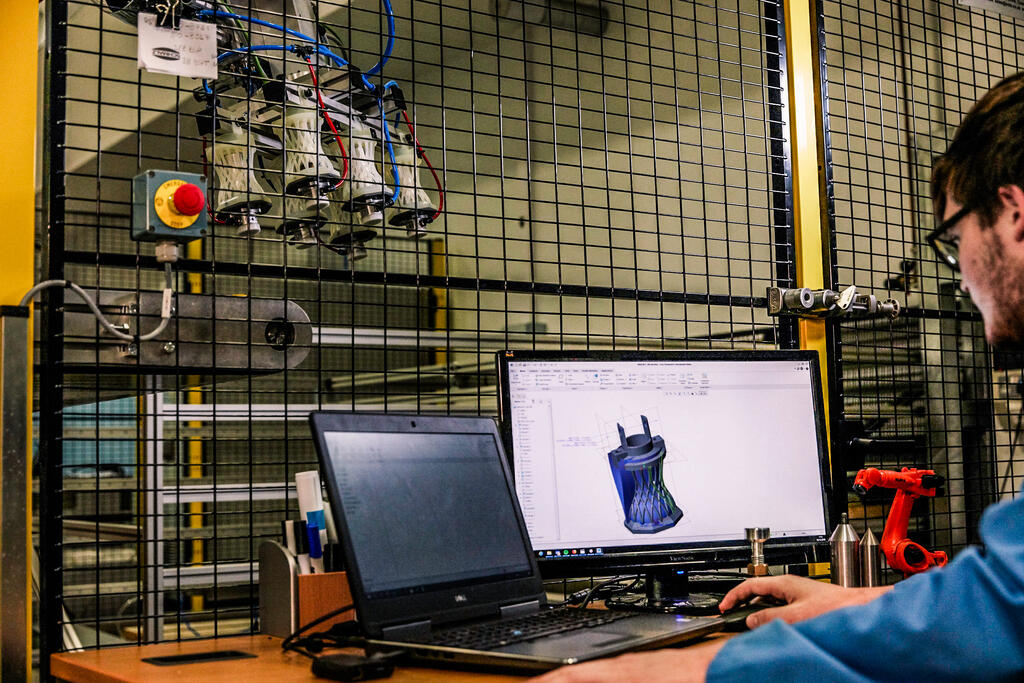

“Much like the large-scale SLS High Speed Sintering machine being developed by the AMRC and the University of Sheffield’s AdAM Centre, the bank of 3D printers allows multiple parts to be built in each print run for shorter lead times and quick turnaround on component builds,” explained Mark.

Formlabs – who started out of MIT in 2011 and now have over 500 people across Boston, North Carolina, Hungary, Germany, Japan, and China – have been following Mark’s ambitious project with keen interest and recently came to witness how it was stimulating innovation and productivity improvements across the AMRC itself.

The projects the company saw included the batch production of 500 high-precision drilling caps that were critical to prevent cross-contamination during aerospace drilling trials; the 3D printing of highly intricate brackets for a pick-and-place robot that automates composites’ manufacturing; fixturing for a sensor-mounting system for an autonomous welding project; and the printing of customer rollers for a composite filament winding machine. All of these are now featured in a series of short films that can be seen here.

“We often hear about companies that try to adopt 3D printing, but purchase expensive machinery that ends up standing idle in a corner—because of its complexity and limited accessibility, only a select few can use it. The AMRC’s open access bank with the Form 2 3D printers and post-processing units is a brilliant model that other companies can easily replicate to solve this challenge and empower hundreds of engineers to support their work.

"The wide range of applications we saw across multiple AMRC sites proves that once equipped with these versatile and easy to use tools, engineers will find ways to integrate them into their workflows, savings time, costs, and increasing efficiency," said David Lakatos, Chief Product Officer at Formlabs.

“The projects are really great examples of the breadth of applications AM can be used for,” said Mark. “But we also want to show industry how accessible this technology is for even the smaller companies we work with and demonstrate how batch-quantity bespoke AM is possible right now, at a good price point.

For companies interested in engaging with the Formlabs 3D printing bank at the AMRC, please contact Mark Cocking on 0114 222 6244 or m.cocking@amrc.co.uk.