Optimisation of FDM composite lay-up tooling for additive manufacture

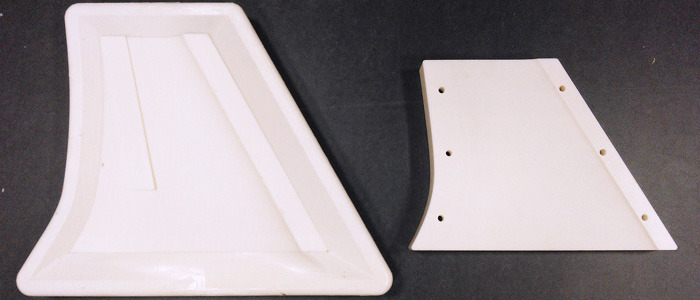

Researchers at the AMRC Design & Prototyping Group have succeeded in cutting the time take to make a suite of carbon composite layup tools by more than 45 per cent, while reducing the amount of support material needed by more than 80 per cent.

The Group designed and additive manufactured (AM) the tools as part of a larger project.

The initial AM tool design followed a somewhat traditional form and the savings were achieved by applying design for additive manufacturing principles, using, amongst other things, tool path data, including the width of deposited material bead, generated by the software associated with the production equipment, a Stratasys Fortus900mc.

Downloads

Optimisation of FDM

- 1.12 MB