AMRC’s robot research cuts the cost of producing aircraft components for BAE Systems

Austin Cook, BAE SystemsOur work with the AMRC is on track to save BAE Systems millions of pounds in capital and operational costs over the coming years.

A research project to enable robots to accurately machine holes in composite aircraft components, has matured into a production system and is on track to save BAE Systems millions of pounds in capital and operational costs over the coming years.

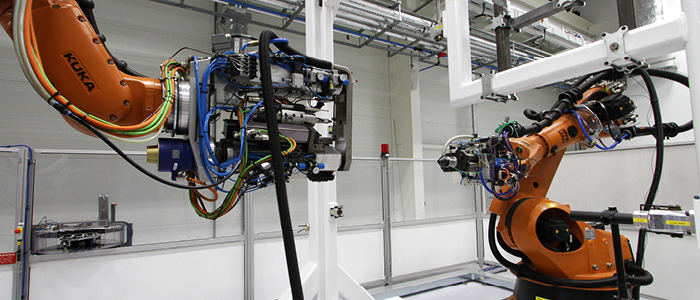

The robotic countersinking technology was developed through collaborative research, led by the AMRC and involving KUKA Systems UK.

The development technology derisked the process enabling the design of a production system.

This production system has now been installed at BAE Systems in the UK, where it will be used to processes a wide range of composite components for military aircraft.

Downloads

- 1.25 MB