Vehicle conversion firm plugs in to Virtual Reality to boost production

02 July 2018A family-run vehicle conversion firm is embracing Virtual Reality technology to boost productivity and reduce turnaround times for designing and kitting out vehicles for customers.

A team from the Integrated Manufacturing Group (IMG) at the University of Sheffield's Advanced Manufacturing Research Centre (AMRC) worked with Clarks Vehicle Conversions to show how it can use Virtual Reality (VR) to revolutionise the design stages of converting a vehicle and that with some clever optimisation of its CAD models, the process time can be improved and complexity reduced.

Clarks Vehicle Conversions (CVC), based in Doncaster, kits out vehicles such as welfare vans, lifestyle vehicles and crew carriers to clients’ individual specifications. Customers include firms such as National Rail, Enterprise and Lex Autolease.

Currently, when a job comes in for CVC, a skilled team of fitters, electricians, engineers, mechanics and designers has to build a physical prototype to show the customer.

This involves kitting out a van to the customer’s exact requirements. The customer then has to visit the CVC’s Conversion Centre to approve the van layout before it can go into production. However, if the customer wants to make any changes, and depending on the scale of alterations they want to make, this can push delivery time back as it requires the customer to go back to the Conversion Centre to approve the final build for a second time.

IMG Digital Software Engineer, Jake Senior, showed the company how established VR technology could be used to transform the design stage of a conversion by allowing the customer to wear a VR headset and ‘build’ a virtual prototype to their own specification - rather than having to wait for a practical demonstrator to be built, reducing the turnaround time between an order being placed and the vehicle leaving the shop floor.

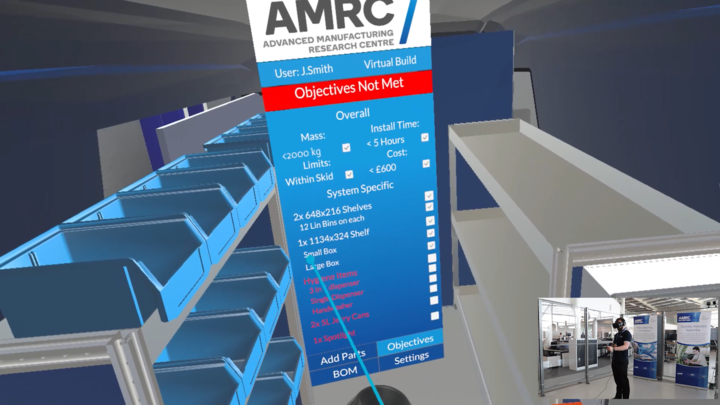

Jake used the company’s existing CAD models to recreate an empty van in the virtual world where the customer can pick items from a displayed bill of materials and place them in the van where they want them to go. The bill of materials also list the mass of each item selected, the installation time and cost – updating in real time whenever a new item is chosen.

The idea is the customer has full control over the design process which minimises the risk of them wanting to make changes down the line due to a wrong layout. It also means when the customer is happy with the fit out in the virtual world, the design can be rubber stamped and sent for manufacture.

The use of VR technology to help with design and prototyping slashed the ‘order to manufacture’ turnaround time from up to six weeks down to 30 minutes.

IMG’s project manager for SMEs, Matt Bacon, said: “CVC knew they wanted to utilise VR technology in regards to kitting out vans but didn’t know how to go about it or what the technology is used for, what the benefits are and which is the best tech to use. They just knew it was there, holistically.

“It was up to us within that five days to demonstrate the functionality of some of this VR kit specifically. We wanted to show them what we could do and what was achievable.

“The company were happy. We had some good feedback. They are digesting the information we’ve given them and then we can start planning out a roadmap in regards to the kind of projects we feel they need to complete to get a fully integrated system to replicate the VR demonstrator.”

Matt also carried out some CAD optimisation work in relation to geometries inside the vans – replacing CVCs tried and tested method of using cardboard to convert curved surfaces into flat panels with a simpler and quicker digital process.

The company currently uses traditional skilled prototype build engineers to profile the inserts by hand to determine panel sizes. Instead of profiling by hand into a void on a panel and then flattening this out to convert the curved surface into a flat panel for machining, Matt created digital geometries to make the process easier.

CAD models used during assembly were also streamlined as they were too detailed and data hungry, making it difficult to run and manipulate the model due to lack of process power. Matt overcame this by making sure all the necessary features were available to reference but without the need of manipulating an entire assembly, improving the process time and reducing complexity.

The packages of work by the IMG group were carried out during a five-day funded project that is part of the AMRC’s commitment to SME engagement, funded by the High Value Manufacturing Catapult.