Ffatri 4.0: Sustainable manufacturing and assembly

Helping manufacturers measure sustainability credentials through scope one, two and three emissions

Challenge

Manufacturing companies are being encouraged to understand their impact on the environment through scope one, two and three emissions. Across the industry, manufacturers of all sizes are being asked to report on their sustainability targets, like carbon footprint analysis, alongside cost challenges they may be facing associated with inflated energy bills.

Larger corporations have entire teams devoted to their sustainability journey, but the same can’t always be said for small to medium-sized enterprises (SMEs). And in both instances, there seems to be a lack of understanding on where to start.

As part of the wider Ffatri 4.0 research programme to create a blueprint for productive, sustainable and resilient factories, AMRC Cymru explored the collection and application of data in relation to reducing the environmental impact of a process.

It looked to educate all partners and provide them with a credible ability to formally assess the impact of a manufacturing process. With this approach, project partners can collect the right data by asking the right questions.

The project framework supports industry in three key areas:

- Scope one emissions:

Understanding what Green House Gas (GHG) emissions a company makes directly, for example: production processes, facilities usage (heating, lighting), company vehicles.

- Scope two emissions:

Indirect emissions from the generation of purchased energy, from a utility provider. In other words, all GHG emissions released in the atmosphere from the consumption of purchased electricity.

- Scope three emissions:

Identifying the carbon footprint - such as ingredients, parts, waste, employee travel - through data analytics.

Background

Funded by the Welsh Government, the Ffatri 4.0 research programme aims to aid SME manufacturing companies in the assessment and reduction of the environmental impact of their processes using a framework assessment tool.

Ffatri 4.0 is a collaboration between the University of Sheffield Advanced Manufacturing Research Centre (AMRC) Cymru, Airbus and The Pudding Compartment. It looks at how business can continue to increase productivity while meeting net zero carbon emissions targets through smart technologies. It is based on the premise that the sustainability and productivity goals of the manufacturing sector can be accelerated through the successful adoption and integration of digital manufacturing technologies.

The Sustainable Manufacturing and Assembly project demonstrates the universal nature of sustainability assessments across two extremely different business sectors; in aerospace with Airbus - pioneers of sustainable aerospace - and in food and drink with The Pudding Compartment - an award-winning manufacturer of tray bakes, cakes and wrapped goods.

Ffatri 4.0 is a ready-to-go framework with proven success that will create a blueprint for future manufacturing companies and their associated supply chains. Through implementation and use of Industry 4.0 digital technologies, the framework will improve business resilience, support businesses to achieve world-class standards in productivity and support businesses on the journey to reach net zero by 2050 through efficiency improvements.

The Ffatri 4.0 R&D programme used internal expertise from AMRC Cymru, industrial partners and external expertise through Small World Consulting, whose research and consultancy pushes for systemic change by challenging and supporting organisations to take meaningful, effective actions for a sustainable economy and society.

Innovation

Scope one and two emissions assessment

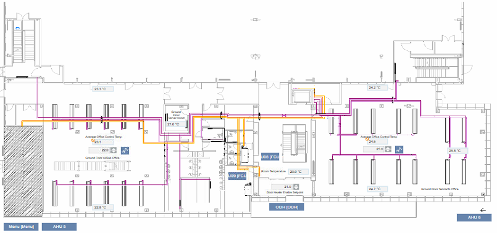

The first task was to understand what utilities were in use and what data could be gathered from methods already in place. Where there were no existing methods, equipment was implemented so data could be captured for analysis. The focus was mainly on electricity, gas, water usage and waste produced at AMRC Cymru.

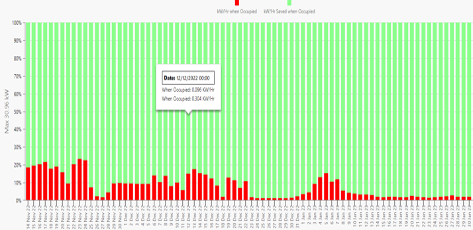

Once data had been collected over time, AMRC Cymru performed analysis of usage and created dashboards showing usage, helping to identify improvement areas where tangible cost reductions could be made.

Scope three emissions assessment

Small World Consulting used its Carbon Footprint Analysis tool to assess the impact of The Pudding Compartment through its supply chain, with the results showing the greatest contributors to the company's emissions.

From here, Small World Consulting and The Pudding Compartment were able to use a scenario-modelling and target-setting tool that allows potential improvements to be assessed based on their impact to the baseline carbon footprint.

Result

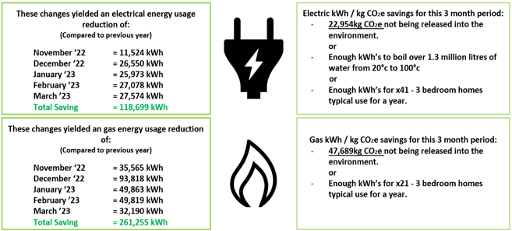

By optimising heating and lighting over a five-month period, AMRC Cymru and Airbus demonstrated electricity savings equivalent to powering 41, three-bedroom homes for a year and gas savings equivalent to powering 21, three-bedroom homes for a year.

By optimising the lighting within its facility, the company has seen a reduction in electricity usage of almost 20 per cent. These significant savings have been achieved with minimal additional equipment or expenditure, while assessing when, where and how the facility is being used and how the business can improve its own behaviours.

Impact

With an increasing focus from industry on its own sustainability objectives and also within the supply chain, coupled with the ever-increasing potential of sustainability legislation being brought in by government, the tools adopted to assess scope one, two and three emissions within this project can help manufacturers to start their own journey to correctly identify the best areas to focus on within their supply chains.

If you’re an SME manufacturer looking to better understand your energy usage, increase productivity, reduce your carbon footprint and improve sustainability in your supply chain, then please get in touch by heading to our website and filling out our form.

AMRC Cymru can work with SME manufacturing companies to implement the Ffatri 4.0 sustainability framework in your workplace.